This machine is the professional solution for the application of the transfer film on the leather and tissue and for quilting continuous even film with double protection.

The KOBRA machine has been designed to ensure the best performance in terms of productivity and final results with regard to special processes and films with high capacity (for example paint). The structure of the machine designed to be able to apply the film and different materials in a flexible and fast way.

The particular system of distension of the film and of the inserted material ensures a smooth ironing.

The operating parameters controlled by a PLC and displayed on a touch-screen control panel.

Features:

- Innovative heating system integrated into the roller, which guarantees significant energy savings, with oil bath electrical resistors inserted inside the roller, allowing to eliminate the external control unit for heating the diathermic oil.

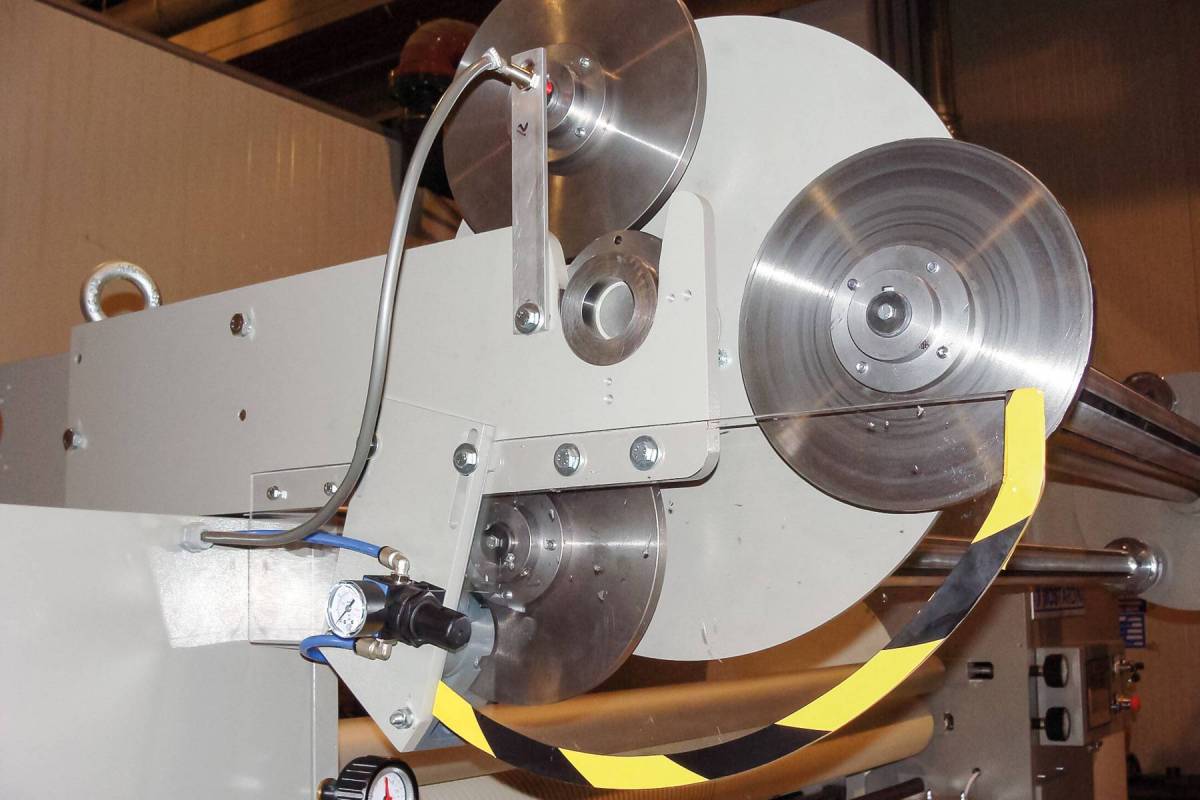

- Unwinding system with 3 stations.

- Winding system at the exit with 1 motorized position.

- Expander roller for film transfer.

- Rubber transport roller.

- Dual conveyor belts anti folds system, to hold the leather in the ironing process.

- Non-stick conveyor belt at the exit.

- Automatic centering system for conveyor belt at the exit.

- Smoothed working roller and transport roller independent motorized with the possibility of adjusting the

thickness. - Electric motors controlled by inverter.

- PLC with “touch screen” panel for programming and control of all parameters (position of rollers, working speed, roller temperature, daily and weekly programming for activation preheating roller, diagnostic problems, ect ).

- Safety devices in accordance with the regulations.

Options:

- Re-winder and un-winder devices for fil and winding system at the exit with 2 motorized positions.